- de

- en

- es

- mx

The Internet of Things (IoT) consists of objects that are able to communicate with each other and the people in their surrounding area. This networking of man-machine as well as machine-machine leads to several processes becoming autonomously controlled and no longer requiring human intervention. This means that the control can be administered decentrally, which strengthens the autonomy and therefore also the local adaptability (flexibility).

Our connected supply chain connects the objects and the people involved in the value-added chain. Information is exchanged on an open platform with standard protocols. In addition, smart devices and mobile equipment are being increasingly used.

The goal is to transfer as many process steps as possible to decentralized units, optimally with swarm intelligence, in order to increase flexibility.

Real-time tracking of containers using the cloud

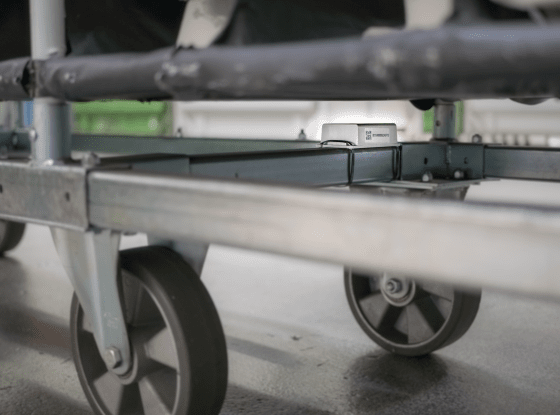

In order to increase the transparency of the container locations and to optimize transport, the JIS containers are continuously tracked in real time on their way from the picking to the customer’s assembly line. For this, the containers are equipped with smart transmitters that transmit their location at short intervals.

All movements are transmitted online and assessed in real time. In the next step, the processed information is sent to the Schnellecke Cloud, which is based on the SAP Hana Cloud Platform, where it is stored and processed. As well as the site data, the order data from our SJS system is also transferred to the Schnellecke Cloud. In this way, the progress of the processing status of the orders and containers can be tracked in real time.

All information is aggregated in the Schnellecke Cloud and visualized clearly in a digital dashboard. In this way, our employees and our customers can immediately determine where the necessary JIS containers are located. Disruptions or bottlenecks can be easily detected and eliminated with appropriate measures. As well as on desktop PCs, this dashboard is also available as a mobile version for smartphones.

Besides the real-time tracking of the containers, the system offers the possibility to calculate the cycle times using historical data, thus enabling the determination of the process times, which can then be used to dynamically adjust the order control to the cycle time of the assembly line.